From concept to installation

We cover the production procress from start to finish, within one company

Our services include all construction and installation steps, precisely according to your requirements. We are pleased to de­velop custom made concepts for you, and manufacture according to our high quality standards. In addition, we are certified in accordance with DIN EN ISO 9001:2008.Extensive material checks are part of the daily routine for us: samples of every raw material delivery are extensively tested. And that is even though we only buy the appropriate primary materials from certi­fied, renowned suppliers.

During the manufacturing process, there is also continual monitoring of the produc­tion. That way we ensure a consistently high quality standard.

Of course, we would be pleased to provide you with our knowledge and experience at any time, for pre-installations and super­ visions.

Production: Milling and boring machines

Because every detail is relevant to safetey

According to customer requirements and specification, the appropriate boring and milling profiles are used. For the crea­tion of NC codes we work with CAD pro­grammes for a precise three dimensional view of the component, to rule out possible sources of defects even before series pro­duction.

The anchor ring and load distributor can be processed in all designs and dimen­sions. We also offer coating of the seg­ments in a variety of RAL tones, or even hot-dip galvanising or zinc spraying.

Whatever the design: manufacturing is subject to the strictest quality criteria, and is carried out with the highest precision, as these are safety relevant construction elements.

Processing all components with CNC aid­ed machines guarantees absolute dimen­sional precision.

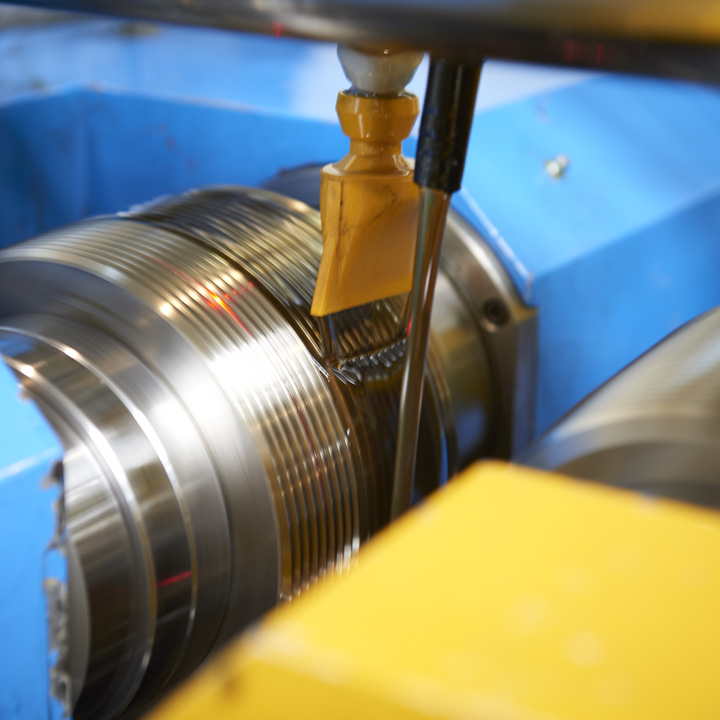

Production: Thread rolling machine

Highest precision is the top priority

In order to fulfill our customer«s require¬≠ments, our machinery also includes a thread rolling machine with a rolling power of up to 600 kN. It works with the established 2 carriage technology, and a pressing power of up to 60 t.

We manufacture using a cold forming pro­cedure, and process solid material in the area of a standard thread up to M100, and special productions up to a diameter of 200mm in various thread types.

Thereby, you can choose between uncoated raw or the following coatings:

- Electrogalvanized in accordance with DIN 50961, DIN EN ISO 4042

- Hot-dip galvanized in accordance with DIN EN ISO 1461, DIN EN ISO 14713

- Zinc flake coating in accordance with DIN EN ISO 10683 with defined coefficients of friction (Delta tone / Delta seal)

- Further coatings on request

In addition we supply anchor bolts, according to your exact requirements.

Intelligent production

Our innovation for quick and easy installation: our anchor basket

Wind energy has become a supporting column in the area of energy generation. In order to give wind power plants a more secure and stable base, we developed the innovative and patented anchor basket KLAS in 2009.

With these product characteristics, we provide a foundation for your efficiency:

- Construction aids are superfluous when installing our anchor basket. You benefit from quicker installation times due to the parallel and independent erection

- Installation errors due to incorrect handling of templates, are ruled out right from the start

- You save the transport costs for the return transport of templates

Incidentally: For the manufacture of our anchor bolts and/or double ends, we use steel blanks in strength classes from 8.8 to 12.9. In order to be able to guarantee con­sistent quality of the primary materials, we have all batches tested with a spectral analysis, by an external laboratory.